Build on the basics of safe forklift operation

What can you do to minimise lift truck accidents? In this article we first reinforce the fundamental principles. We then point you to further clear guidance for a deeper understanding of the risks and solutions.

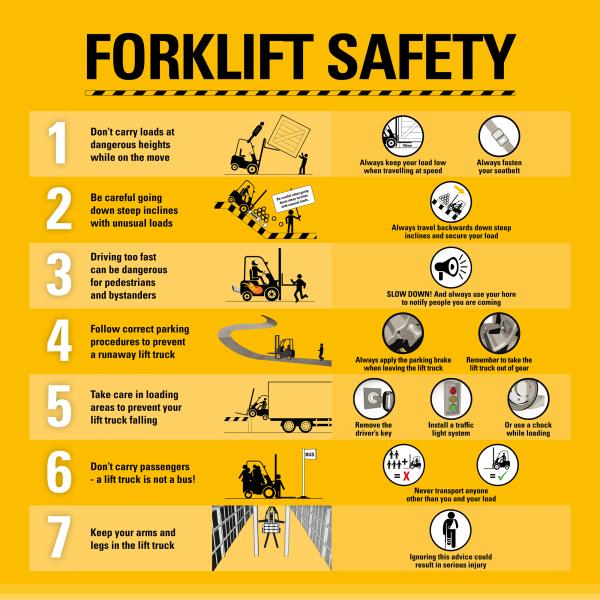

Safety is a big priority for Cat® Lift Trucks. We build it into our forklifts, and we encourage it through our advisory materials and campaigns. If you want a safer workplace, being aware of the most common forklift operating mistakes is a good starting point. We’ve identified seven key issues or ‘deadly sins’ that put lives and health in danger. Workers should be regularly reminded of them. We have a short animation (on the right-hand side) and a downloadable poster to help with this.

Below, we’ve highlighted those seven forklift safety tips and expanded a little on each one. We’ve also given links to other Cat Lift Trucks articles which advise in more detail.

1. Overturning

Don’t carry loads at dangerous heights while on the move. Keep your load low when travelling at speed.

In our list of seven ‘rules’, numbers 1 and 2 are essentially about maintaining balance and stability. Rule 3 is also relevant here, as excessive speed – especially when cornering – can make forklifts unstable. At its extreme, loss of balance can cause a lift truck to overturn. But even a relatively small incident involving instability can be enough to make a forklift spill its load.

We look more deeply at stability in our ‘Keep your balance’ article. This contains additional guidance on fork height and on best practice for slopes. It also gives advice on: cornering; driving smoothly; checking surface conditions and overhead clearances; correct loading; and adjustment for the nature of the load. Finally, forklift drivers are reminded to wear a seatbelt, if fitted. It won’t prevent an overturn, but it can save your life if an overturn happens.

That article includes information on the Cat® Responsive Drive System. Amongst other benefits, RDS helps to keep drive and hydraulic actions smooth and stable. The specific truck mentioned is no longer in production, but you will find RDS on most Cat electric counterbalance forklift models.

2. Spilling loads

Be careful going down steep gradients with large or unusual loads. Travel backwards in that situation, and make sure your load is safely secured.

See the information above, under ‘1. Overturning’. Our ‘Keep your balance’ article is all about keeping your load on the truck and your truck’s wheels on the floor.

3. Driving too fast

Driving too fast can be dangerous for pedestrians and bystanders. Slow down! And use your horn so people know your truck is coming. This is especially important at cross aisles and doorways.

As well as endangering people, speeding increases the risk of damaging collisions with structures and objects, including walls, racking and equipment. Those accidents may additionally result in spillage and damage of goods. In some cases, as we have already mentioned, a forklift cornering too quickly may overturn.

Lift truck operators must, of course, use their judgement to decide what is a sensible speed at any moment. That means not too fast but not too slow. What’s needed is an optimum level that maintains productivity as well as safety.

Forklift developers can help operators to work quickly but safely and confidently through good design and engineering. Key factors include the lift truck’s manoeuvrability, ergonomics, operator view, precision of movement, and smoothness of control. Our article on speeding up materials handling discusses these. Another of our articles, on safety at speed, looks at automated aids to achieving optimum motion.

4. Parking without braking

Forklift runaways are surprisingly common. Follow correct parking procedures to make sure your truck stays in place. When leaving your lift truck unattended, always apply the parking brake and take it out of gear. Ideally, you should also lower the forks.

For extra confidence, you can choose forklifts with automatic parking brakes. When the truck becomes inactive, with no driver in the seat, a parking brake is automatically applied. This feature can be found on all Cat electric counterbalance forklifts, as well as Cat reach trucks, low-level order pickers and various others.

5. Falling from docks

Lack of care in loading areas can result in you and your truck dropping from a great height. Make sure the vehicle being loaded/unloaded doesn’t move. You can do this by, for example, removing the driver’s keys, installing a traffic light system, or simply using a chock until loading/unloading is complete.

Loading docks are sometimes described as the most dangerous places in the materials handling world. They are busy environments with multiple interactions between goods vehicles, lift trucks, their drivers, and co-workers. A lot can go wrong. It might sound crazy, but accidents frequently result from lorries being driven away before the loading or unloading is finished.

Smaller movements of a vehicle may also be enough to create a gap into which a lift truck or worker may fall. Steep gradients between a vehicle’s load floor and the dock are another potential hazard, as containers may unexpectedly slide or roll. Rain can add extra slipping dangers. These problems, and their solutions, are explained further in our article on safety in the loading dock. In a subsequent article, we explore technological approaches to loading dock safety. These include wheel locking, trailer brakes, electro-hydraulic dock levellers, sealed dock houses and more.

6. Carrying passengers

Never transport anyone or anything other than yourself and the load.

What more can we say on this subject? A lift truck is not a bus! Passengers can’t be carried safely on it. Nor should you ever be tempted to lift someone on the forks. If you do, you may well add to the already substantial industry statistics for falls from height.

7. Leaving limbs unprotected

Keep your arms and legs inside of the truck while moving. Ignoring this advice could result in serious injury.

To stay safe, operators should stay completely within the truck’s dimensions and protective structures. In our article on protecting lift truck operators’ limbs, we look at design features and technologies adding extra safeguards. As well as physical defences, they include a variety of approaches to keeping the operator safely in place.

But first of all…

Before operating any lift truck, the operator must receive appropriate training. See our article on forklift operator training for important advice on that. And before starting each working day or shift, operators must carry out the necessary lift truck daily checks. Our clear guidance on that topic helps users to recognise signs of emerging problems. If defects are discovered, you shouldn’t operate the truck until the relevant manager has decided it’s safe to do so.

More advice on forklift safety and related topics can be found on our blog and in our Eureka online magazine.